About this product

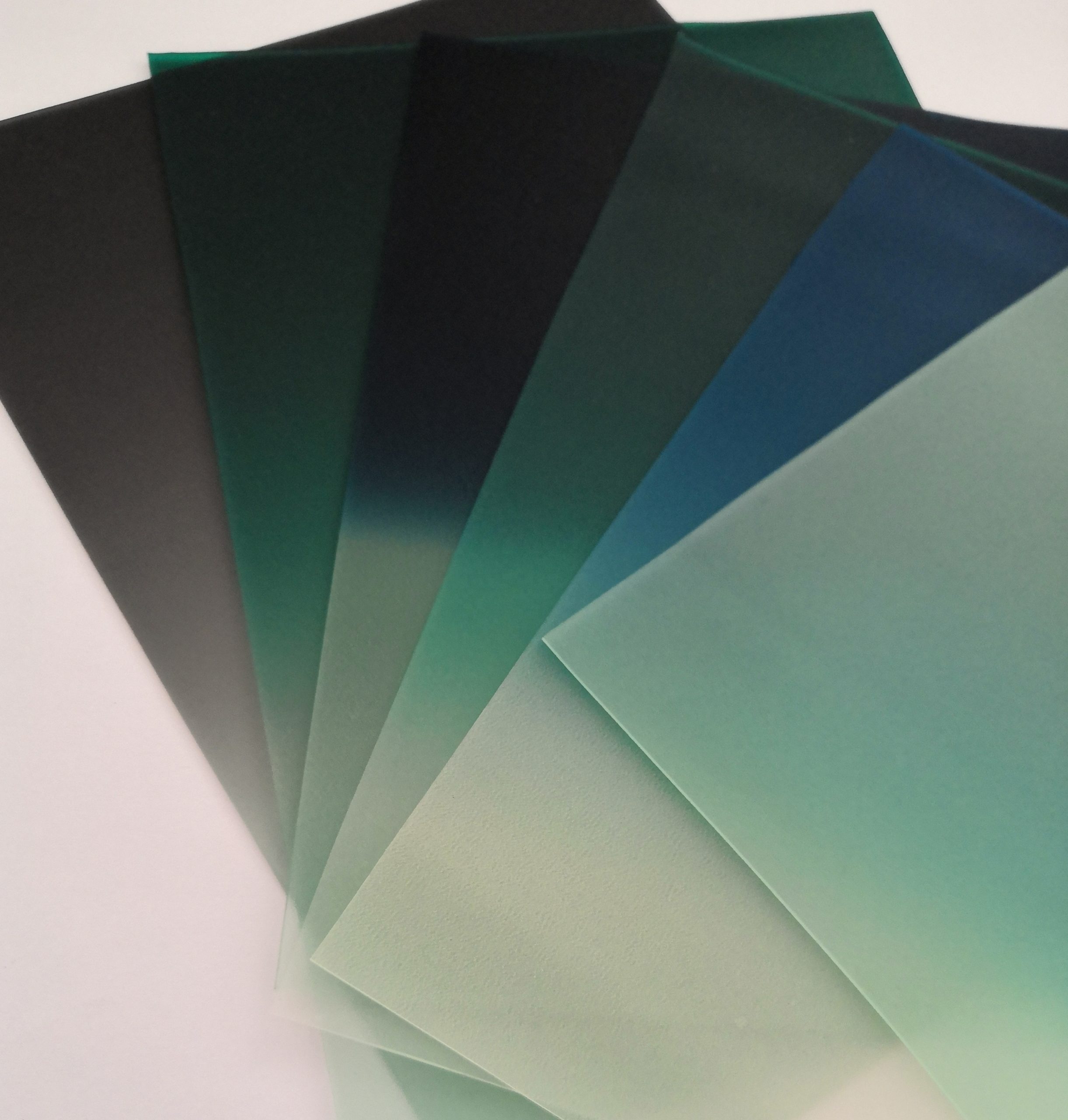

PVB interlayer is mainly used for laminated glass. There are some types of interlayers made from other materials such as EVA (Ethylene-Vinyl Acetate). PVB interlayer has the unique advantage of adhesion to the glass, penetration and impact resistance.

Because of its shatterproof function, PVB interlayer for laminated glass is used in many ways where safety and security are required, such as automobile windshields, side door windows and architectural glass. In the automotive industry, the use of laminated glass for windshields is mandatory in almost all of countries such as the U.S, Europe and Japan. The role of glass in terms of comfort and design as well as safety and security is expanding as more bright and open spaces are required today. PVB Interlayer is attracting attention as technology that can enhance the possibilities of glass.